Versatile PTFE Resin Micropowders

Part of the Chemours family of fluoropolymers, this product is a white, free-flowing polytetrafluoroethylene (PTFE) resin used as an additive in other materials and systems.

Unlike PTFE granular and fine powders, Zonyl™ micropowders have:

- Small particle sizes ranging from 2 to 20 µm

- Low molecular weight

- Different particle shapes and morphology

- Versatility that allows use over a wide temperature range

Depending on how they are handled and processed, these micropowders provide nonstick properties and improve lubricity, wear resistance, and reinforcing properties.

Zonyl™ micropowders are primarily intended for use as micropowders in mixtures with other solid or liquid materials that can:

- Enhance abrasion resistance

- Reduce the coefficient of friction and mechanical wear

- Reduce surface contamination

- Modify appearance

Features and Benefits of Zonyl™ Micropowders

A wide variety of industries depend on Zonyl™ micropowders for specific benefits, such as their ability to infuse hosts with some of PTFE's more unique properties.

Some applications include:

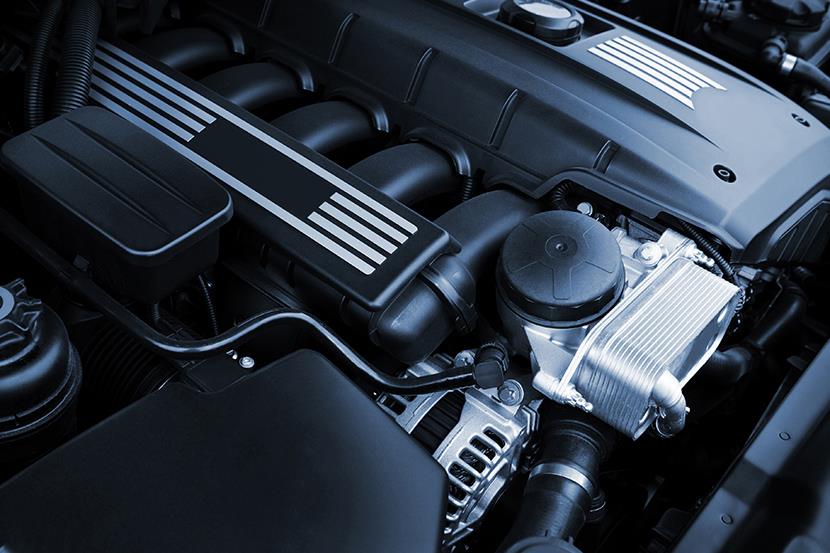

- Thermoplastic parts, like gears, benefit from improved wear resistance, reduced friction, and elimination of stick-slip behavior.

- Diverse environments that use elastomer seals see improved tear and abrasion resistance.

- Lithographic, flexographic, and gravure inks gain better image protection and higher productivity.

All-purpose solid lubricants can use Zonyl™ micropowders alone in powder form or in a paste or spray. When dispersed in water or organic solvents, the powder provides another option for direct or additive use. In paste form, it's able to protect wear surfaces in hostile environments and improve the performance of high-performance sealants.

Chemours recommends against using Zonyl™ micropowders as molding or extrusion powders because of their inherent low molecular weight. Learn more about safe handling and use in the individual product technical data sheets.

Choosing the Right Zonyl™ Micropowder

Zonyl™ micropowders come in a range of product grades, with characteristics that affect the process and performance of desired end products.

Many factors influence selecting the correct additive, including:

- Particle size, distribution, and form

- Dispersibility

- Surface area

- FDA compliance/EEC food approval

No Universal Formula

The plastics, inks, and elastomers industries use many processes to produce a wide range of products. Even small differences in these processes or host materials may require different powder characteristics to achieve the desired result. Zonyl™ micropowders provide the right combination of powder characteristics to enhance the effectiveness of the host materials and meet diverse application needs.

For detailed information, see the table below. To discuss your specific industry and application needs, please contact us.